Filter

Gravity and Pressure Filters

The Water Aeration Filtration Unit (WAFU) ® is our proprietary patent-pending water treating unit comprising aeration and filtration processes in a single vessel. The innovation reduces equipment cost, total installed cost, and simplifies the operation and ongoing maintenance. It can also reduce the footprint needed for the equipment.

The technology was developed by WETS to address issues of our clients who were experiencing problems, particularly in iron and manganese treatment. WETS LLC, in its 45-years history, has designed, constructed, and installed hundreds of individual aeration and gravity filtration systems, the majority of which included iron and manganese removal from water. We have had numerous projects concerning the rehabilitation of iron/manganese treatment units to address fouling issues. The iron and manganese precipitates are designed to be removed in the filtration unit but frequently deposit in the aerator, on the aerator packing, and in the piping to the filtration unit. Also, due to the fouling, there is increased bacterial growth on the packing as portions of the packing are not exposed to the chlorine in the water.

The dual media sand-anthracite filter is primarily used for the removal of turbidity and suspended solids as low as 10 to 20 microns. Dual media filters provide very efficient particle removal at relatively high filtration rates. State administrative codes typically set specific requirements for filtration and other water treatment systems, including parameters such as media depth and maximum filtration rates.

While the dual media sand-anthracite filter is still the workhorse for water treating, other filter media that better target specific contaminants have been developed over the years. WETS has years of experience with these alternate media and through this experience and our pilot study program, we can identify the best filtration solution for your water quality issues. WETS has experience in the use of filtration for the removal of color, taste and odors, iron and manganese, arsenic, microbial contaminants, THM’s, and radium and uranium. Please see our Contaminants section for more information on filtration in these specific applications.

Removing suspended solids in a granular media filter is a complex process involving several phenomena. It is important to properly match the filter selection and design with the pretreatment requirements. Attempts to develop a quantitative theory for design applications have not met with much success; a successful design is based on experience and practice. For this reason, a pilot study is typically required for a proper design. Over the years, WETS has developed strong capabilities in pilot study execution; we consider our ability to design and perform pilot studies quickly and at a very reasonable cost to be a clear differentiator for our company.

Much of the objectionable material in water can be of colloidal size, and will not be removed by sedimentation or standard filtration. It is often necessary to add a chemical to cause these extremely small particles to collect into clumps or “floc”, particles that are too large to pass through the interstices of the filter. These chemicals are referred to as coagulants.The mechanism of coagulation involves using positively charged metal ions to attract the negatively charged colloidal particles which are otherwise repelling each other (virtually all the suspended particles in natural water have a negative charge).

Coagulation in water treatment processes is affected by a number of different factors, such as pH, salts concentration, temperature, type of coagulant, turbidity, etc; so, for any particular water, obtaining effective coagulation can be a challenge. Coagulant aids have been found to improve the properties of the floc for filtration, by making the floc more durable or more rapidly settling. For these reasons, jar testing and/or field pilot testing are often necessary to determine the best means of coagulation and solids removal. The common water treatment coagulant chemicals are aluminum sulphate (Alum), ferrous sulphate (copperas), ferric sulphate, and ferric chloride. Common coagulant aids include anionic polymer, non-ionic polymer, sodium silicate, bentonite, and calcium carbonate.

The filter media eventually becomes plugged with the solids/precipitates and can no longer readily pass water. This is noted by an increase in headloss on the filter gauge. When this occurs the filter flow must be reversed to flush the solids and precipitates out of the filter media. The backwash expands the bed 30 to 50%, which allows the lighter floc and foreign matter to be carried off, and also allows the sand particles to scour each other. The backwash water must be clean filtered water. The water can be the water from other parallel filter units or clean water from storage.

For smaller municipal or utility district water systems, backwashing is typically a manual operation, where an operator turns the valves. However, some systems have been fully automated; these systems typically initiate on time, perhaps once a week. Ineffective backwash allows the filter media to become more permanently fouled/coated. Such media will require replacement to maintain performance. Therefore, there are various techniques to improve and enhance backwash.

Backwash processes include:

- Water‐only backwash, which is simplest and most common. Filter flow is reversed, with clean water pumped through media at relatively high rates. An ideal backwash flow will expand a filter bed 30‐50 percent, allowing particulates caught in voids to be carried up and out of the filter.

- Surface‐wash sweeps. Surface‐wash sweep systems use rotating “sweeps” that spray water at high velocities at the surface of the media during backwash. The sweep causes the media grains to collide, which helps remove contaminants stuck to the media. The prevention of mudball formation, cracks, particle growth, and cementation, as well as an increased length of filter runs, are some of the benefits of surface-washing.

- Air scour developed for the wastewater market, air scour reduces the amount of energy required to fluidize media and reduces the amount of backwash water and backwash rate. For sequential and simultaneous air‐water backwash, the air is introduced below the media and allowed to rise through the media. The rate at which air rises through the water creates high levels of energy that provide for aggressive contact between media grains. Compared with water‐only or surface‐wash techniques, the procedure significantly improves the amount of adhered contaminants removed from the media.

The typical nominal backwash rate is 15 GPM/ft2. The backwash rate is typically lower when a surface wash is employed. A backwash rate can be optimized based on taking cores samples of the filter before and after the backwash. A proper backwash rate is critical; a too low rate will not properly clean the bed, regardless of backwash duration (as the bed will not be properly expanded); too high a rate will disrupt the bed, reducing filter performance and effectiveness. The typical backwash time is 8 to 10 minutes.

Sub-optimal backwash can lead to the formation of mudballs, which are spherical aggregates of solid material (typically one inch in diameter) formed by the gradual build-up of material not removed by the backwashing process. They typically form at or near the surface of the sand but will begin to sink down if the problem is not addressed. A surface wash can help prevent the buildup of mudballs. Proper design of the collection troughs is essential for a well-performing backwash system. A properly designed trough allows for the prompt removal of wastewater and minimizes the formation of mudballs.

The underdrain performs two primary functions. The underdrain uniformly collects the filtered water to maintain a constant rate of filtration across the filter bed and passes the water to the outlet of the filter. A more important function of the underdrain is to evenly distribute backwash water so that the gravel subfill is not disturbed and the filter media is evenly expanded.

The WETS proprietary underdrain is a simple design that can provide better performance and a longer filter bed life than the more expensive and complicated designs of established filter vendors. The two basic filter types utilized by WETS are the gravity filter and the pressure filter. The pressure filter is an ASME pressure vessel, typically constructed of low-carbon steel. The gravity filter is typically an ambient pressure vessel made of fiberglass.

Gravity Filter

In a typical gravity filtration system, the water to be treated is fed from the wellhead pump to an elevated aerator, with the water gravity-flowing from the aerator through the filters, which are installed on the ground. The water is pumped from the filters to the GST/hold tank. Gravity filters can be cylindrical or rectangular. Very large capacity filters are often long rectangular vessels. These rectangular vessels are typically concrete or steel plate, depending on project specifications and local costs/conditions.

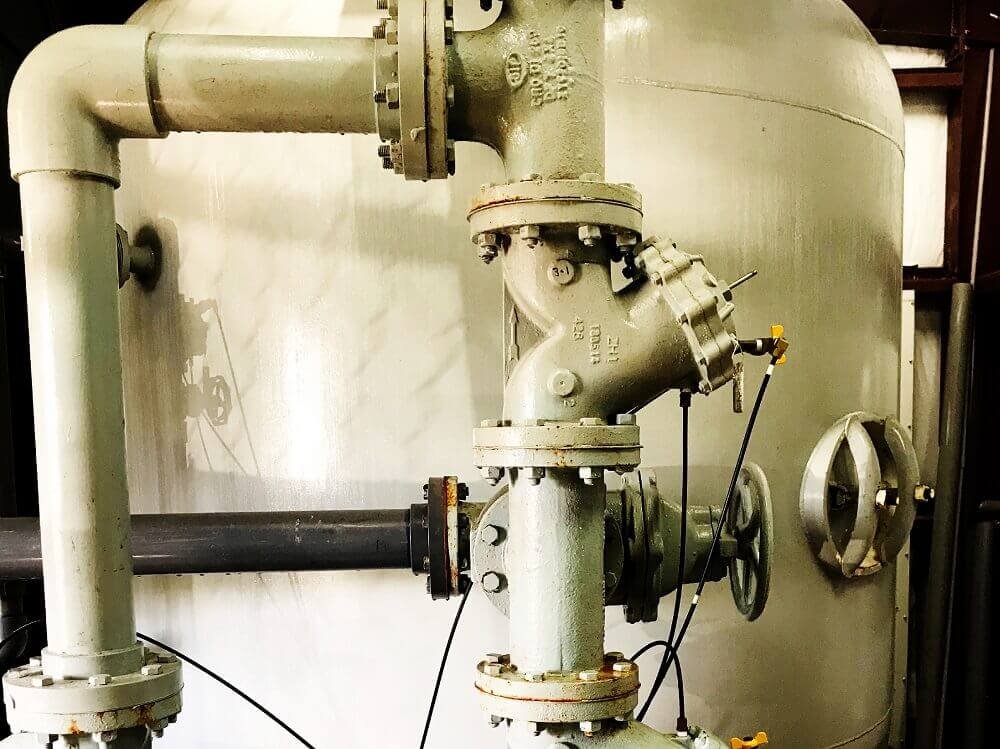

Pressure Filter

The typical water pressure filter application involves a system where aeration is not required, and the system can therefore be kept under pressure from the wellhead pump through to the GST or the distribution system.

The pressure filter is an ASME pressure vessel, typically constructed of low-carbon steel. WETS offers vertical or horizontal pressure filters designed to fit the footprint available; vertical filters are often ideal for smaller flows and buildings accommodating higher headroom but compact footprints. Horizontal filters are used in applications requiring greater capacity, but these filters can pose challenges in the proper design of the backwash.

Solutions to Your Water Treatment Needs

Whether you want a new water treatment system installed, need your current one inspected and repaired, or just want a free quote, contact the WETS LLC. With years of experience in the industry, our skilled team members are trained and knowledgeable with a variety of leading water equipment and products. Our certified water purification experts are here to help.